Commercial and industrial facilities rely on reverse osmosis (RO) systems to produce high-purity water for manufacturing, food and beverage processing, boiler feed applications, pharmaceuticals, and countless other uses. As water treatment requirements continue to grow more complex, one component has become increasingly vital for system performance: the pump skid.

A well-designed pump skid system integrates the pumps, instrumentation, valves, piping, and controls into a single, pre-engineered assembly. Instead of piecing together individual components on-site, pump skids deliver a turnkey solution that dramatically improves RO performance, energy efficiency, and long-term reliability.

At Advancees, our PS Pump Skids are engineered specifically for commercial and industrial RO systems, structured to reduce installation time, simplify operation, and extend the lifespan of downstream components.

Why Pump Skids Are Critical for RO System Efficiency

1. Consistent Pressure for Optimal Membrane Performance

Reverse osmosis membranes require precise, stable pressure to function properly. Even minor fluctuations can reduce permeate quality, increase energy usage, and shorten membrane life.

A pump skid ensures:

-

Continuous, stable pressure

-

Smooth flow delivery with minimal pulsation

-

Correct hydraulic performance across varying demand levels

This stability helps protect membranes from unnecessary stress, ultimately lowering operational costs.

2. Plug-and-Play Design Reduces Installation Time

Traditional RO system installation involves sourcing pumps, valves, pipe fittings, gauges, and control systems separately. This increases labor hours, creates compatibility issues, and raises the risk of installation errors.

Pump skids eliminate that complexity.

Because the entire assembly is pre-fabricated, tested, and packaged, contractors benefit from:

-

Faster startup

-

Fewer field modifications

-

Reduced integration errors

-

Lower installation costs

This “ready-to-run” format is a major reason pump skids are trending across the water treatment industry.

3. Improved System Monitoring and Automation

When paired with a centralized control system, pump skids give operators clearer visibility into performance metrics like flow, pressure, temperature, and pump status.

A dedicated control panel allows operators to:

-

Automate pump sequencing

-

Monitor real-time system health

-

Integrate alarms and safety protections

-

Reduce manual adjustments

-

Improve overall system uptime

Many facilities are moving toward smart automation, and a pump skid combined with a proper control panel makes this transition seamless.

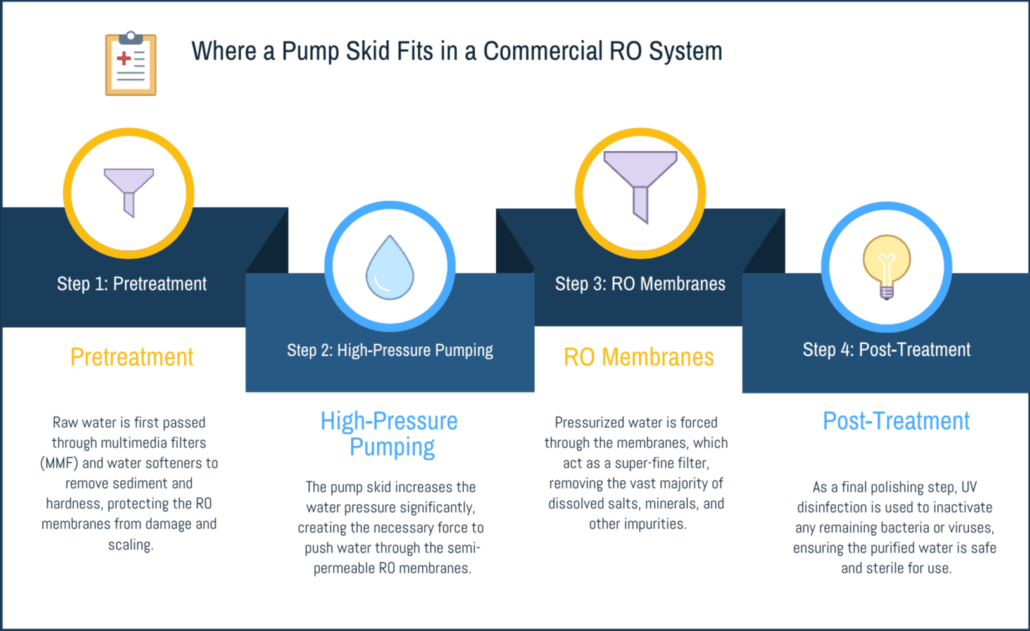

Where Pump Skids Fit Within a Complete RO Treatment Train

Pump skids are only one part of a larger water treatment process. To understand their impact, it helps to look at their placement within the system.

A typical commercial RO setup includes:

1. Pretreatment Stage

Before water reaches the pump skid, it must pass through pretreatment equipment that protects downstream components.

Key pretreatment technologies include:

-

Multimedia Filters (MMF) – Remove sediment, turbidity, and suspended solids

-

Water Softeners – Reduce hardness to protect RO membranes

Proper pretreatment is essential because solids, scale, or organics can damage high-pressure pumps and cause membrane fouling. A pump skid works most efficiently when fed high-quality water from a stable pretreatment system.

2. High-Pressure Pumping (Where the Pump Skid Operates)

Once pretreatment is complete, the pump skid drives water into the RO membranes at the correct pressure. This is the heart of the system and directly impacts:

-

Production rate

-

Permeate quality

-

Membrane life

-

Energy usage

With a dedicated skid, the entire pumping operation becomes easier to manage, maintain, and optimize.

3. Post-Treatment and Disinfection

After water passes through the RO membrane, post-treatment steps may be required depending on the application.

A common choice is ultraviolet water treatment, which eliminates microbiological contamination without chemicals.

UV disinfection is especially valuable when:

-

Storing water in tanks

-

Supplying water for food or beverage production

-

Meeting NSF/ANSI safety standards

Together, pretreatment, pump skids, and post-treatment form a complete, efficient RO water purification process.

Energy Efficiency: A Major Advantage of Modern Pump Skid Systems

Commercial RO systems often operate for long periods, so energy efficiency is a key factor in long-term operating costs. Pump skids help improve efficiency through:

-

Proper pump sizing

-

Efficient hydraulic layouts

-

Reduced friction losses

-

Optional VFD (variable frequency drive) integration

-

Lower electrical demand

By optimizing flow and pressure, facilities see reduced energy costs and extended equipment life—two major advantages for high-demand applications.

Lower Maintenance & Minimal Downtime

A consolidated skid reduces the number of individual components that require manual checks. Maintenance teams benefit from:

-

Clearly labeled valves and gauges

-

Organized piping

-

Easy access to pumps and fittings

-

Fewer connection points that could leak or fail

Many facilities also appreciate the compact footprint, which saves space in crowded mechanical rooms.

Why Facilities Are Transitioning Away from Custom-Built Pump Installations

Historically, pump systems were constructed on-site using standalone pumps, scrap skids, loose wiring, and manually assembled piping. This approach comes with several challenges:

-

Increased risk of leaks

-

Difficulty troubleshooting

-

Poor component compatibility

-

Extended downtime during repairs

-

Traditional systems lack standardization

Pre-engineered pump skids solve all of these issues by offering a consistent, factory-tested package built to industry standards.

Final Thoughts: Pump Skids Make RO Systems More Reliable and More Efficient

As commercial and industrial RO systems continue to evolve, pump skid systems have become essential for achieving stable operation, energy savings, and dependable water quality. When combined with strong pretreatment, smart controls, and proper post-treatment, pump skids help facilities operate more efficiently while minimizing maintenance and downtime.

ADVANCEES offers fully engineered PS Pump Skids specifically designed for RO applications, providing the reliability and performance needed for high-demand environments.