As water quality standards rise and industrial RO systems become more advanced, selecting the right disinfection method has never been more important. For decades, chlorine, chloramines, and chemical oxidizers dominated the industry. But today, ultraviolet water treatment has emerged as a preferred option across commercial and industrial applications due to its effectiveness, safety, and compatibility with modern RO membranes.

Whether you manage a food plant, pharmaceutical facility, beverage production line, or any industrial process requiring biological control, understanding UV vs. chemical disinfection helps ensure water safety and system efficiency.

ADVANCEES offers high-performance UV Ultraviolet Disinfection systems engineered for reverse osmosis post-treatment, helping facilities maintain microbiological safety without chemical risks.

Why Disinfection Is Essential in an RO System

Reverse osmosis membranes can remove many contaminants, but biological growth is still a major threat. RO membranes:

-

Do not kill microorganisms

-

Can be damaged by oxidants like chlorine

-

Create low-nutrient environments that still support bacterial colonization

-

Are prone to biofilm formation

A strong disinfection strategy, especially in downstream distribution and storage, is essential to prevent:

-

Biofouling

-

Product contamination

-

RO membrane damage

-

System downtime

-

Regulatory failures

This is where disinfection choices matter.

Ultraviolet Water Treatment: A Chemical-Free Alternative

Ultraviolet (UV-C) disinfection uses light at approximately 254 nm to destroy microorganisms by damaging their DNA. It inactivates bacteria, viruses, protozoa, and algae without chemicals, making it ideal for RO systems.

How UV Benefits RO Applications

-

No risk of membrane oxidation

Chemicals like chlorine degrade RO membranes. UV does not. -

Instant, on-demand treatment

No contact tanks or mixing required. -

No change to water chemistry

UV does not affect taste, odor, pH, or conductivity, essential in food and pharmaceutical applications. -

Highly effective against protozoa

Organisms like Giardia and Cryptosporidium are chlorine-resistant but are easily inactivated by UV. -

Environmentally friendly

No residuals, no chemical storage, no hazardous by-products.

Chemical Disinfection: Still Useful, But With Drawbacks

Chlorine, chloramines, peroxide, and ozone have been widely used in industrial water treatment. They remain valuable for municipal treatment and long-distribution piping loops, but in RO environments they present challenges.

Chemical Disinfection Advantages

-

Provides residual in long piping systems

-

Useful for high-load biological water sources

-

Strong oxidizers can break down organic contaminants

-

Familiar to many facility operators

But There Are Significant Drawbacks for RO

-

Chlorine damages RO membranes

Even trace levels can cause irreversible membrane oxidation. -

Creates harmful by-products

Trihalomethanes, chloramines, and other regulated DBPs. -

Requires chemical storage and handling

Safety risks increase for industrial staff. -

Changes water chemistry

Especially problematic in beverage, food, and pharmaceutical applications. -

Slow contact time

Requires retention tanks, extra piping, and system footprint.

For these reasons, many modern facilities now use chemicals only before certain pretreatment stages, never near membranes or final product water.

Where UV Fits in a Complete RO Treatment Train

One of the biggest advantages of UV is how well it integrates into existing RO systems.

A standard commercial RO configuration includes:

1. Multimedia Filtration (MMF)

Removes turbidity and suspended solids that interfere with UV transmission.

2. FRP Softeners

Remove hardness to prevent membrane scaling.

3. Cartridge Filtration

Captures fine particulates.

4. Pump Skids

Provide consistent pressure for RO membranes.

5. Reverse Osmosis Membranes

Remove dissolved contaminants.

6. UV Ultraviolet Disinfection (Final Step)

Prevents bacteria from entering storage tanks, filling lines, distribution loops, or downstream equipment.

Placing UV at the end of the treatment process ensures microbial protection at the exact moment when water is at its highest purity.

UV vs. Chemicals: Which Is Better for RO?

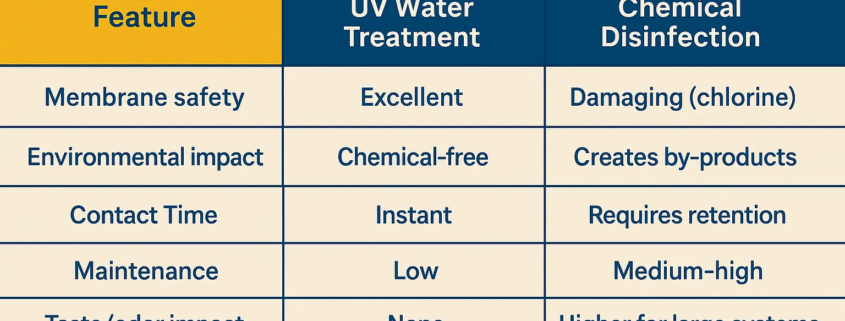

Below is a simplified comparison:

| Feature | UV Water Treatment | Chemical Disinfection |

|---|---|---|

| Membrane safety | Excellent | Damaging (chlorine) |

| Environmental impact | Chemical-free | Creates by-products |

| Contact Time | Instant | Requires retention |

| Maintenance | Low | Medium–high |

| Taste/odor impact | None | Can alter |

| Cost over time | Low | Higher for large systems |

| Effectiveness on protozoa | Very high | Low |

UV wins for most commercial and industrial RO applications, particularly high-purity water needs.

Chemicals may still be useful upstream (before carbon filtration or softening) or in municipal treatment, but UV is the superior solution for final disinfection.

Applications Where UV Outperforms Chemical Disinfection

Industries that rely on UV systems include:

-

Food and beverage production

-

Pharmaceutical and biotech manufacturing

-

Laboratories and hospitals

-

Breweries and wineries

-

Bottling plants

-

Electronics manufacturing

-

Hotels and commercial buildings

-

Aquaculture and hydroponics

Any application requiring stable water chemistry and microbiological safety benefits from ultraviolet treatment.

Final Thoughts: Ultraviolet Water Treatment Is the Smart Choice for RO Systems

Ultraviolet water treatment offers unmatched benefits for RO operations: no chemicals, no by-products, complete membrane safety, and powerful pathogen inactivation. As industrial water purity requirements continue to increase, UV has become the preferred method for protecting RO product water and maintaining high system reliability.

ADVANCEES provides engineered UV systems designed specifically for commercial and industrial RO applications, helping facilities achieve safer, cleaner, and more efficient water treatment.