Ultraviolet disinfection is a means of killing or rendering harmless microorganisms in a dedicated environment. These microorganisms can range from bacteria and viruses to algae and protozoa. UV disinfection is used in air and water purification, sewage treatment protection of food and beverages, and many other disinfection and sterilization applications. A major advantage of UV treatment is that it is capable of disinfecting water faster than chlorine without cumbersome retention tanks and harmful chemicals. UV treatment systems are also extremely cost efficient!

Advantages of UV sterilization

|

|

TO REQUEST A PROPOSAL, EMAIL US Sales@Advancees.com

How Ultraviolet Water Treatment Works

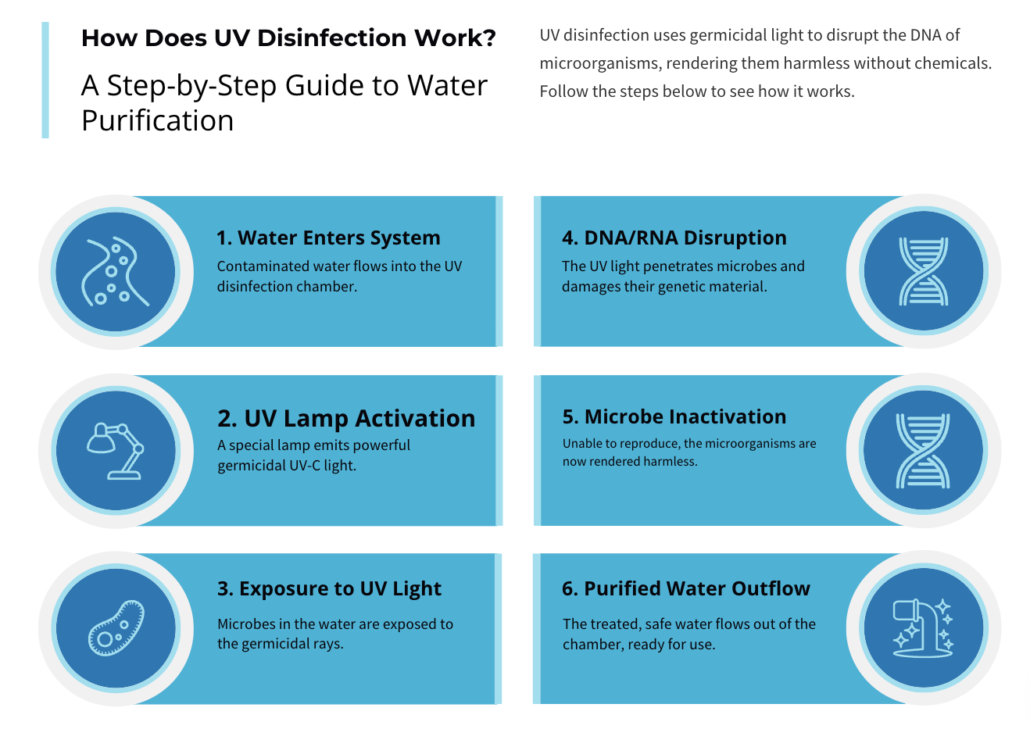

Ultraviolet water treatment uses UV-C light at approximately 254 nanometers, the wavelength most effective for destroying microorganisms. As water passes through the UV chamber, microorganisms are exposed to this germicidal light, which disrupts their DNA and prevents them from reproducing. If a pathogen cannot reproduce, it cannot cause infection, making UV a powerful final step in any water purification system.

A high-quality UV system includes a quartz sleeve, long-life UV lamp, and sensors to monitor UV intensity. These components ensure consistent performance and maximum microbial inactivation.

What Affects UV System Performance?

To ensure effective ultraviolet water treatment, the water must be clear enough for UV light to penetrate. The following factors can reduce UV transmission:

Water Quality Variables

- Iron & Manganese: Levels as low as 0.03 ppm (iron) and 0.05 ppm (manganese) can coat the quartz sleeve.

- Total Dissolved Solids (TDS): High TDS can cause mineral buildup and reduce UV exposure.

- Turbidity: Cloudy water (over 1 NTU) prevents UV light from passing through.

- Suspended solids: Particles larger than 5 microns can shield microorganisms.

Why UV Is Ideal for Reverse Osmosis Systems

- Protection against bacteria in storage tanks

- No chemicals introduced into purified RO water

- Extra security for drinking, cooking, ice makers, and appliances

Applications of Ultraviolet Water Treatment

- Residential drinking water systems

- Restaurants, breweries, and food production

- Hospitals, labs, and medical facilities

- Bottled water plants

- Hydroponics and agriculture

- Marine and RV systems

- Commercial buildings and apartments

- Manufacturing, pharmaceuticals, and cosmetics

Benefits of Choosing UV for Water Safety

1. Eco-Friendly Disinfection

2. Low Operating & Maintenance Costs

3. Effective Against Resistant Microorganisms

4. Does Not Alter Water Quality

5. Safe for All RO and Drinking Water Systems

Industrial Park Coral Springs

18514 Intercontinental Crossing Dr, Houston, TX 77073

Products

Latest Projects

PROJECT DESCRIPTION – Sustainable Seawater Treatment – Coastal community and golf course facilitiesAugust 26, 2025 - 12:02 pm

PROJECT DESCRIPTION – Sustainable Seawater Treatment – Coastal community and golf course facilitiesAugust 26, 2025 - 12:02 pm PROJECT DESCRIPTION – MUNICIPALITY PLANT CONTAINERIZED MODULAR SWRO SYSTEMSJuly 3, 2025 - 4:03 pm

PROJECT DESCRIPTION – MUNICIPALITY PLANT CONTAINERIZED MODULAR SWRO SYSTEMSJuly 3, 2025 - 4:03 pm ADVANCEESPROJECT DESCRIPTION – HIGH TDS WATER RO SYSTEMJuly 21, 2023 - 11:47 am

ADVANCEESPROJECT DESCRIPTION – HIGH TDS WATER RO SYSTEMJuly 21, 2023 - 11:47 am